Home »

Why Choose a Flextur Weld Table Over Your Current Setup?

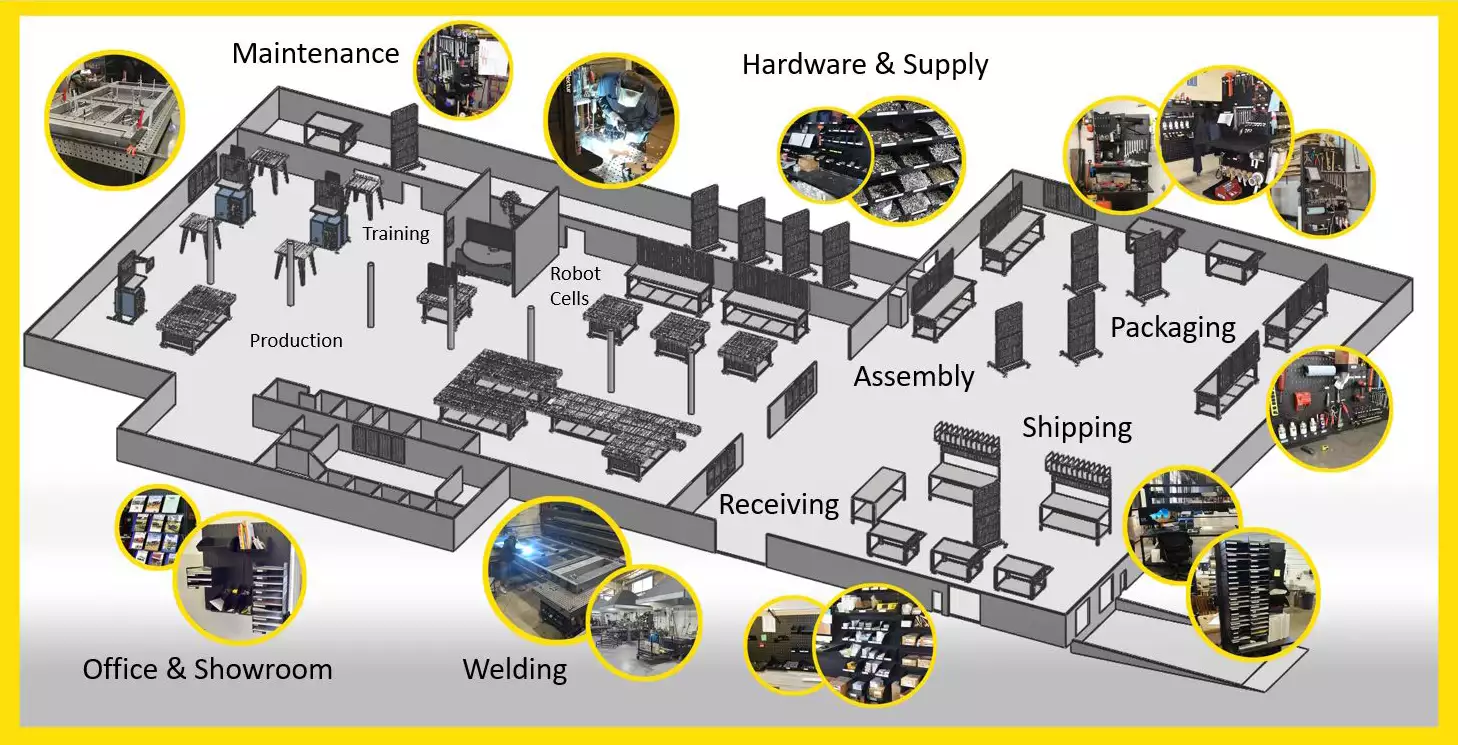

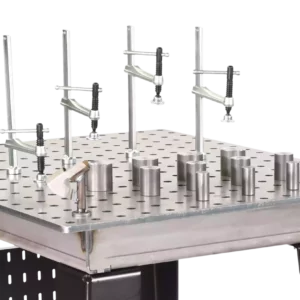

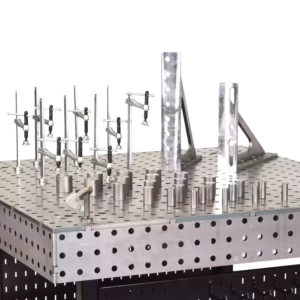

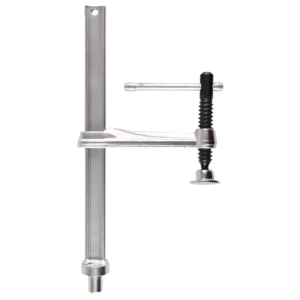

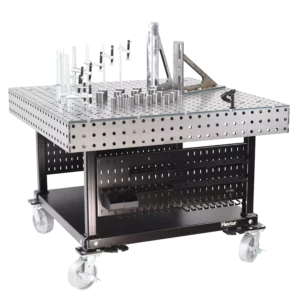

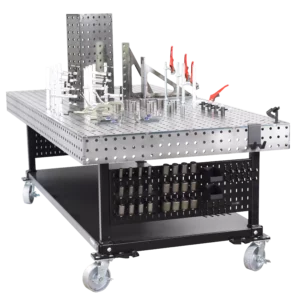

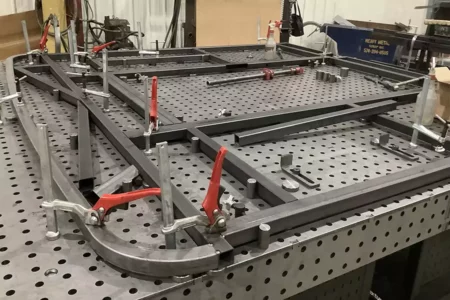

If you currently use a simple steel table, a Flextur Weld Table will open a world of opportunity. Flextur’s 2” grid pattern allows you to locate and clamp materials accurately anywhere on the table. Even vertically. Not just along the edge. Even inexperienced welders can quickly create square, repeatable setups that improve the productivity and quality of every project.

Why Choose a Flextur Weld Table If You Already Have a Jig Table?

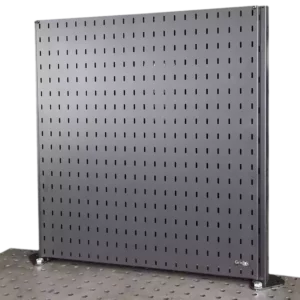

If you’re already using a jig table, Flextur can still offer you opportunities to increase productivity, reduce waste, and lower costs because all our welding tables come with the strongest, most versatile 14-gauge metal pegboard for organizing tools and materials. Putting efficiency within reach. Combine a weld table with a mobile tool board and create a high-efficiency welding station.

Benefits of Flextur Weld Tables

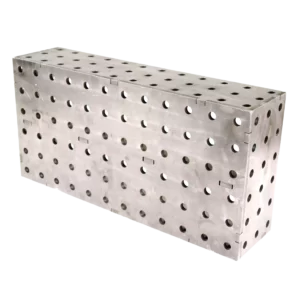

Sold individually, paired with fixturing kits, or as part of a complete Flextur Weld Table Station

Tabletop features a 2” grid pattern supported by a robust strut system

Flextur Tool Board Panels come standard, keeping tools within reach for maximum efficiency

All Flextur Weld Tables and Workstation Systems work together – interlink for maximum capacity and efficiencies within work cells, departments, and facilities

Designed for Lean and 5S workflows

American Made in Dalton, Ohio U.S.A.

Best For These Industries

Aerospace

Agriculture

Automotive

Chemical

Energy / Utility

Food Processing

General Manufacturing

Metal Fabrication

Metal Machinery

Mining

Oil & Gas

Pulp & Paper

Water / Wastewater

Best For These Applications

Welding

Prototyping

Grinding & Finishing

Cobots

Robotic Welding Cells

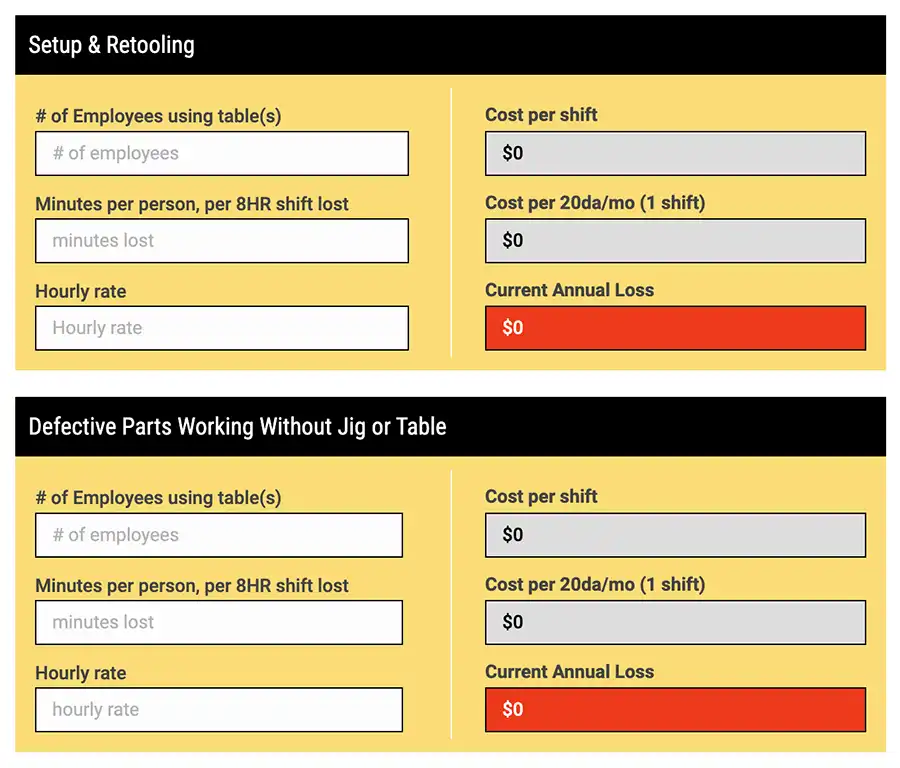

Calculate Your Welding System Payback

Improve Productivity and Efficiency with the Welding Table Payback Analysis

We at Flextur know firsthand before you decide on investing in a significant capital expenditure purchase, analyzing ROI and payback is critical in making the right decision. Below we have provided a tool that we believe will help you in your process.

Improve Productivity & Decrease Waste For Better Profitability

Choosing the correct weld table is complicated, considering all available options and features. Our latest ebook will guide you through the selection process and help you identify the best table(s) to suit your production needs. Discover add-ons and accessories to improve ergonomics, promote employee safety, and increase production efficiency by interlinking and synchronizing your facility.

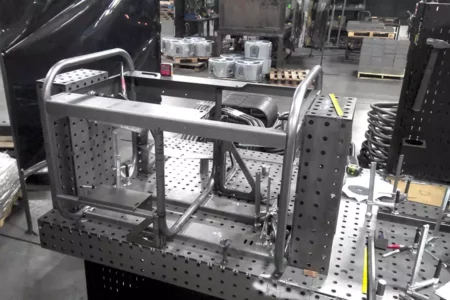

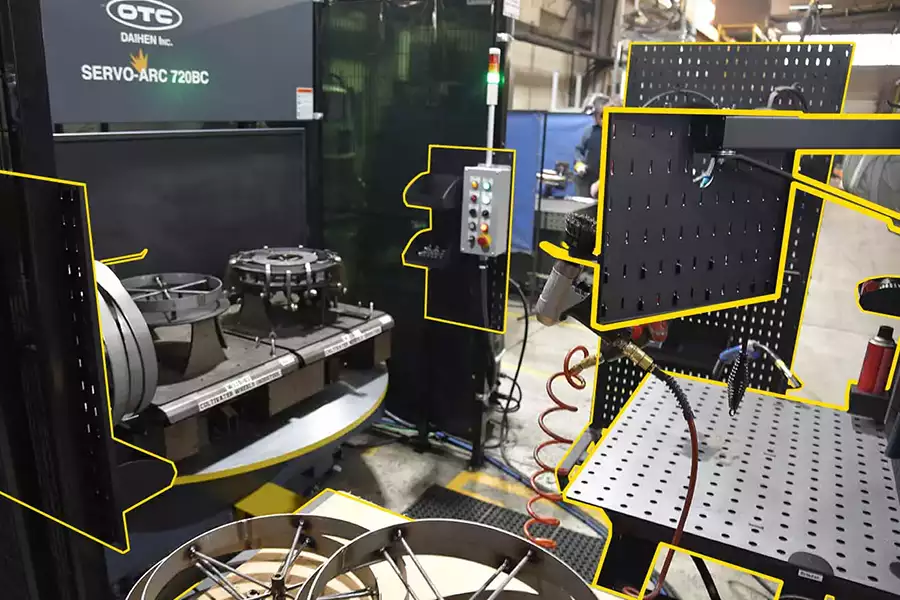

Maximize productivity in Robotic Welding Cells

Let us outfit your facility for maximum productivity

A very agile, very efficient robotic welder is only effective when it's welding. Even the best programming cannot overcome the time spent waiting for materials to arrive. Or to off-load, for that matter. Flextur Workstation Systems can help you get materials to and from the robot in a timely and organized manner. Keep everything within arm’s reach, eliminating wasted steps, bending over, fork truck traffic, and other safety and process problems. When combining metal pegboard panels, a Mobile Tool Board, a Welding Table, and a variety of accessories, you can gain maximum efficiency within your Robotic Welding Cells.

In a similar manner, Flextur products can be combined to increase efficiency in many cobot applications. Mounted to a Flextur weld table or workbench and supplied with products and materials needed through a variety of Flextur products featuring metal pegboard / tool board, you will gain efficiency in your cobot application.

Organize & Standardize Your Facility

Outfit your facility for maximum productivity

By organizing and standardizing your facility using Flextur workstations, tool boards, and accessories, you will decrease labor and material costs, improve product quality, and organize your tool and material storage. Enhance 5S, Lean, and OSHA compliance efforts providing a safer working environment for your employees and visitors.