Cobot Welding System

Unlock the Full Potential of Your Cobot

Whether you’re just getting started with cobot welding, looking to maximize an underutilized cobot, or ready to scale production, Flextur has the cobot welding tables, pedestals, and docking stations to meet you where you are. Our modular, American-made solutions are designed for growth—helping you create efficiency, increase arc on time, improve safety, and keep your cobot welding longer.

Cobot Welding Solutions: Tables for Every Stage of Your Journey

Every manufacturer is at a different point in their cobot welding journey. Maybe you just purchased your first cobot and are working from the small table that came with it. Maybe you’re ready for a larger welding table with precision fixtures. Or maybe you need to maximize throughput with multi-table docking and A-side/B-side or multi-step fixturing production scenarios.

Wherever you are, Flextur provides the tools, tables, and accessories to keep your cobot welding system efficient, safe, and productive.

Our products are designed with one goal in mind: giving you the flexibility to grow at your own pace.

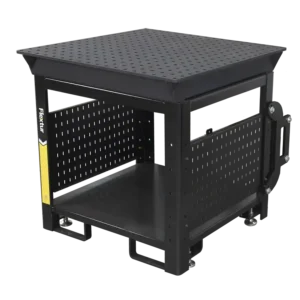

Foundation Stage

The Flextur Cobot Pedestal allows you to mount your cobot arm to any welding surface you already own—freeing up valuable tabletop space and giving you more flexibility right away.

With adjustable height, rigid attachment, and isolated mounting, the pedestal makes your cobot more stable and practical without the cost of a full docking station. It even includes a place to

The Foundation Stage is about making your first cobot welding setup more usable and cost-effective—without overspending.

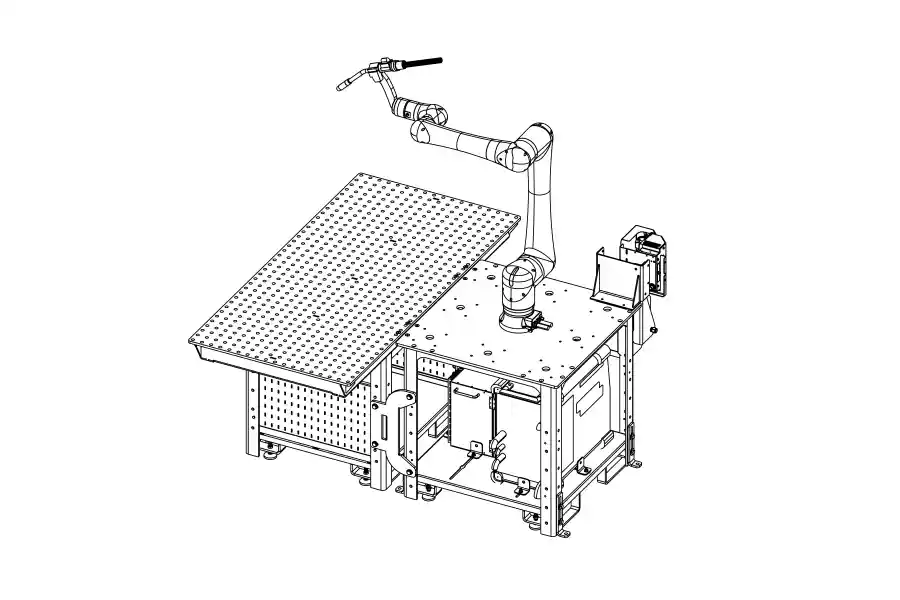

Expansion Stage

As your cobot welding needs grow, consistency and repeatability become just as important as flexibility. The Flextur Docking Station with a combination pin and clamp, or traditional table working side by side with Flextur’s Quick-Change Fixture Table is designed to deliver both.

With precision alignment to within ±0.015", every fixture locks into place exactly the same—ensuring accurate, repeatable welds. Changeovers are faster too. Using pneumatic quick-detach fixture plates, operators can swap plates in minutes and keep the cobot welding with minimal downtime.

The Expansion Stage is about moving beyond the basics into true, repeatable cobot efficiency—with the accuracy and flexibility to take on more work with confidence.

Have questions or want to learn more about the Flextur Cobot Welding System? Schedule a free consultation with our team.

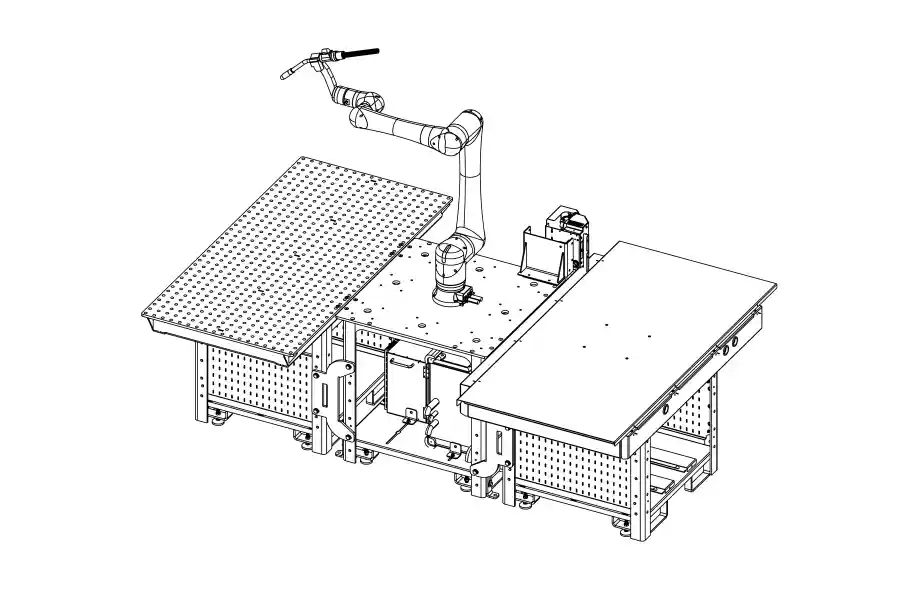

Production Stage

When you reach the Production Stage, it’s no longer about making cobot welding possible—it’s about making it unstoppable. Flextur Docking Stations paired with multiple Quick-Change Fixture Tables are built for continuous throughput, high-mix/low-volume workflows, and side-by-side production.

With A-side/B-side setups, operators can reload one table behind a protective curtain while the cobot continues welding on the other. The result: maximum safety, maximum throughput, and maximum arc-on time.

Customers using our patent-pending Quick-Change Fixture Tables have seen productivity gains of up to 300%, while cutting setup times from 45 minutes to just 5.

The Production Stage takes cobot welding beyond convenience—into high-output automation.

Why Choose Flextur for Cobot Welding?

- Tables for Every Stage – from starter pedestals to docking stations and multi-table systems.

- Maximum Arc-On Time – tables designed to reduce downtime and keep the robot welding.

- Flexible Growth – add only what you need, when you need it.

- Operator Safety – curtains and smart layouts protect your people while the cobot keeps working.

- American-Made Durability – built to withstand the demands of industrial welding.

American Made

Dalton, Ohio U.S.A.

Why Fabricators Trust Flextur Cobot Welding Systems

Ensure Consistency and Quality Control

Quick-Change Fixture Plates position and clamp parts with accuracy within ±0.015", ensuring highly repeatable, automated welds and superior results.

Faster Changeovers

Switch from one part to another in minutes: Release the pneumatic quick-detach Fixture Plate Return it to the storage solution Clamp in the next plate at the touch of a button Select your new program and keep welding

Designed to Scale with You

The modular system grows with your shop—whether you're adding your first cobot or building a fully automated welding cell.

Cobot Welding Q&A

“We have been able to automate quite a variety of products in a cost-effective manner through the quick-change system on the tables. fixtures can easily be moved from station to station with a high degree of confidence that locations are repeatable. The ease of programming and training has minimized the ramp up time to production.”

- Benjamin Vieth, Manufacturing Engineer, Modine, Jefferson City, MO

Our most popular cobot welding systems...

Ready to Grow Your Cobot Welding Capabilities?

No matter where you are on your cobot journey, Flextur has the tools, tables, and systems to help you take the next step with confidence.