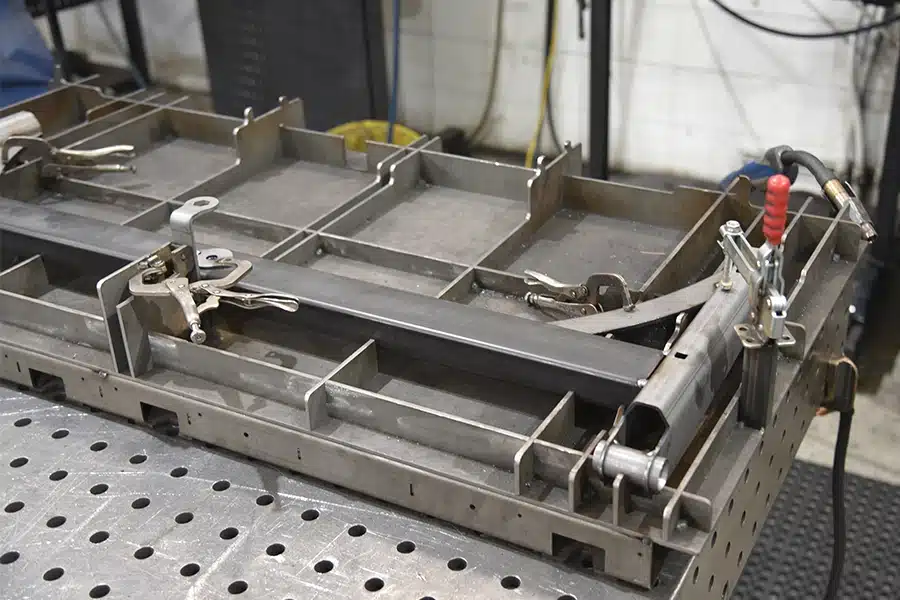

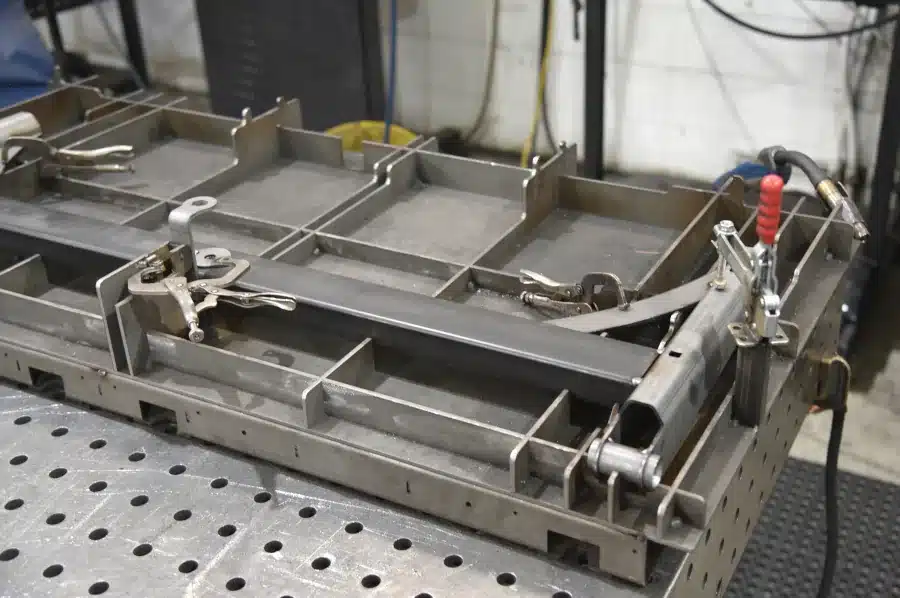

We Build Custom Welding Fixtures

Built for Accuracy. Designed for Efficiency. Engineered for Results.

What if fixtures could be created quickly, affordably, and could be easily and cost effectively modified when things change?

Traditionally, fixtures are extremely expensive, difficult and time consuming to create, and essentially useless if your process shifts. Flextur has a solution – designed to adapt as your needs evolve.

Why Choose Flextur for Custom Welding Fixtures?

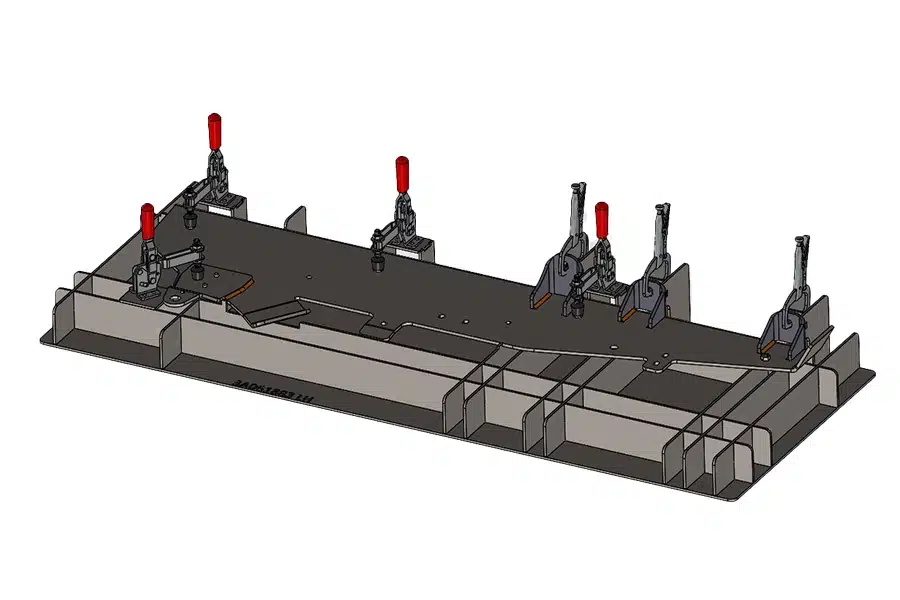

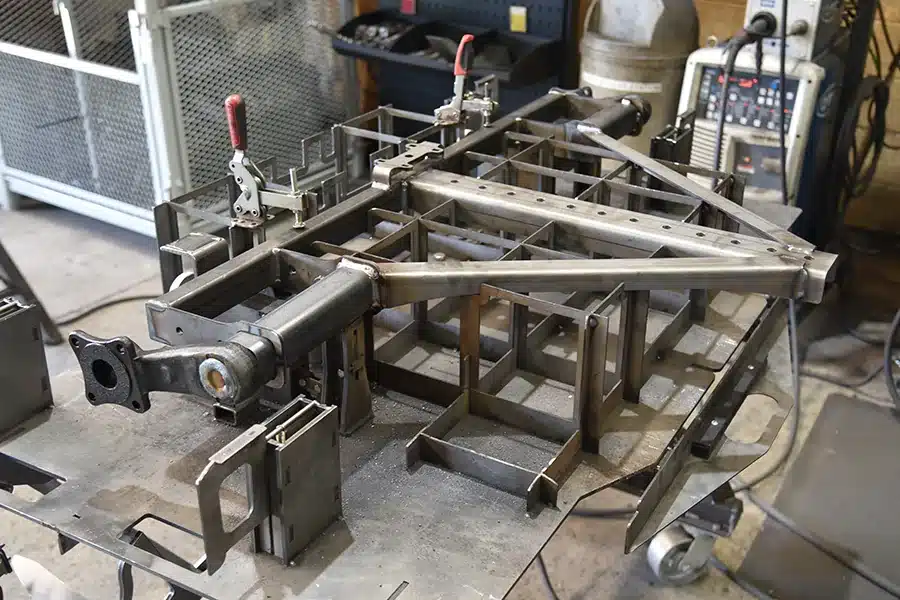

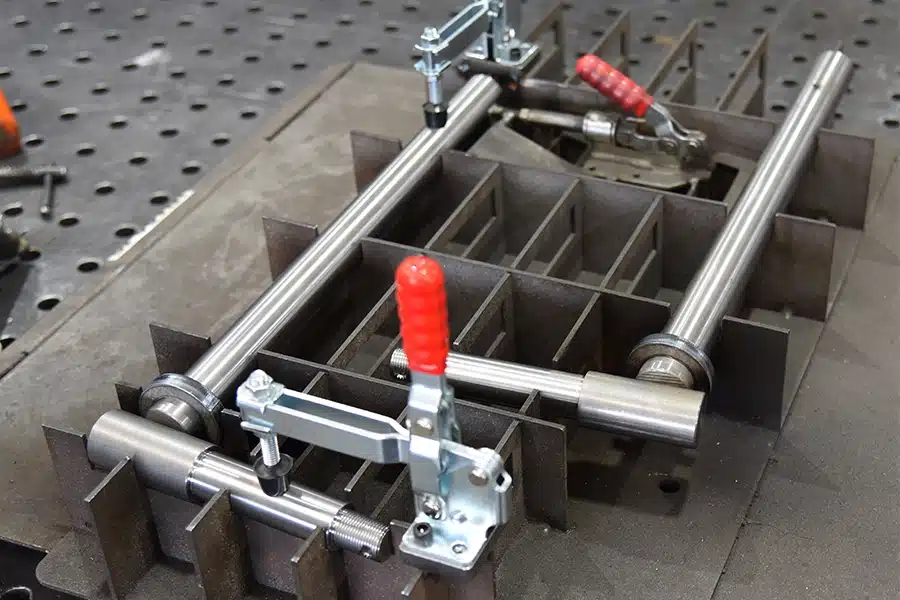

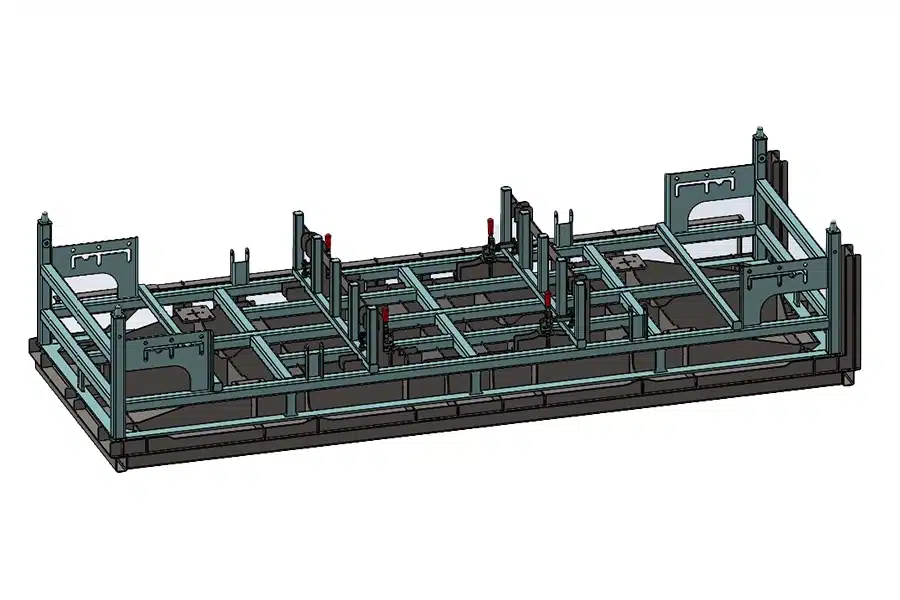

Flextur designs and builds custom welding fixtures that solve the biggest challenge in welding: secure, repeatable part holding. Our fixtures work seamlessly for both cobot welding and manual welding applications. Get high-quality, affordable fixtures—fast—even for low-volume parts. You'll see immediate improvements in weld quality, cycle time, and consistency. From manual setups to fully automated cells with turntables, headstocks, tailstocks, and our Quick-Change Welding Tables, Flextur fixtures are built to deliver real-world results.

Faster, Cost-Effective Fixture Creation

Save time and budget with fixtures designed for rapid setup and ROI that makes sense – even for low-volume parts.

Precision You Can Count On

Achieve exacting repeatability and improve speed, accuracy, and quality in every weld, every time.

Versatile, High-Impact Solutions

From manual welding setups to fully automated systems, turntables, head and tail stocks, or Flextur’s Quick-Change Welding tables – we’ve got you covered.

Affordable Quality, Without Compromise

Many of our fixtures, including engineering and proofing, are priced under $3,000, making high-quality welding accessible for every shop.

Transparent, Customer-Centric Process

Stay in the loop with a well-documented design process and a team that’s always just a call away for questions, concerns, or new ideas.

Clear Communication and a Simple, Proven Process

At Flextur, our fixture design process is transparent and customer-focused. We provide well-documented updates at every stage, ensuring you always know where your project stands. If you have questions, concerns, or new information to share, we’re just a call or message away.

Our Fixture Design Process:

- Project Kickoff: Define the project or part objectives, key requirements, and timeline.

- File Sharing: Provide STEP files once a straightforward NDA is in place, ensuring your designs are protected.

- Budget Review: We present budgetary estimates for approval before moving forward.

- Baseline Setup: Share sample parts to establish baseline measurements and set precise tolerances.

- Design Review: Review and approve detailed fixture design drawings, ensuring alignment with your goals.

- Build and Test: We build and rigorously test the fixture at our facility to guarantee quality and performance.

- Delivery: The completed fixture, along with all test parts, is carefully packaged and shipped to your facility.

Looking for Fixturing Kits?

Need clamps, pins, and brackets for flexible setups? Explore our full line of Welding Fixturing Kits and accessories here →