Flextur is Changing the Game with Innovative Fixture Solutions

Fixture faster, with less expense and greater flexibility

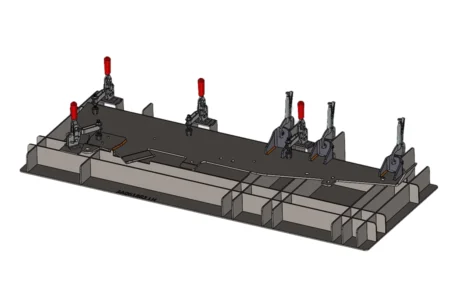

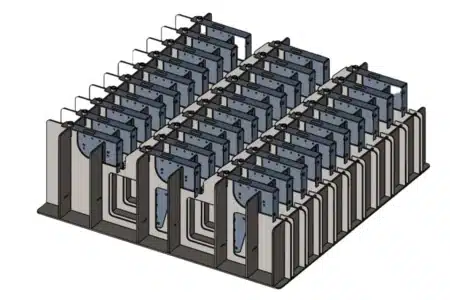

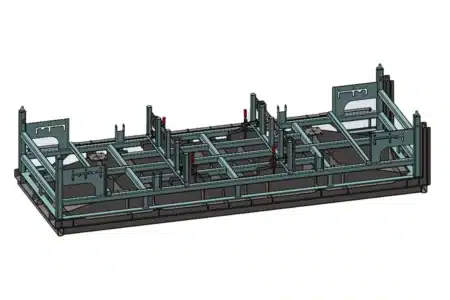

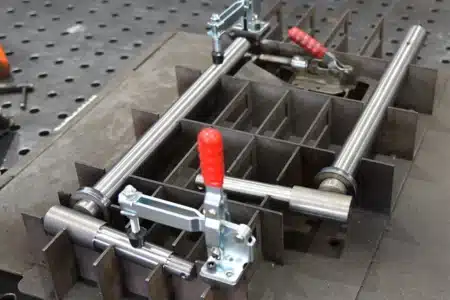

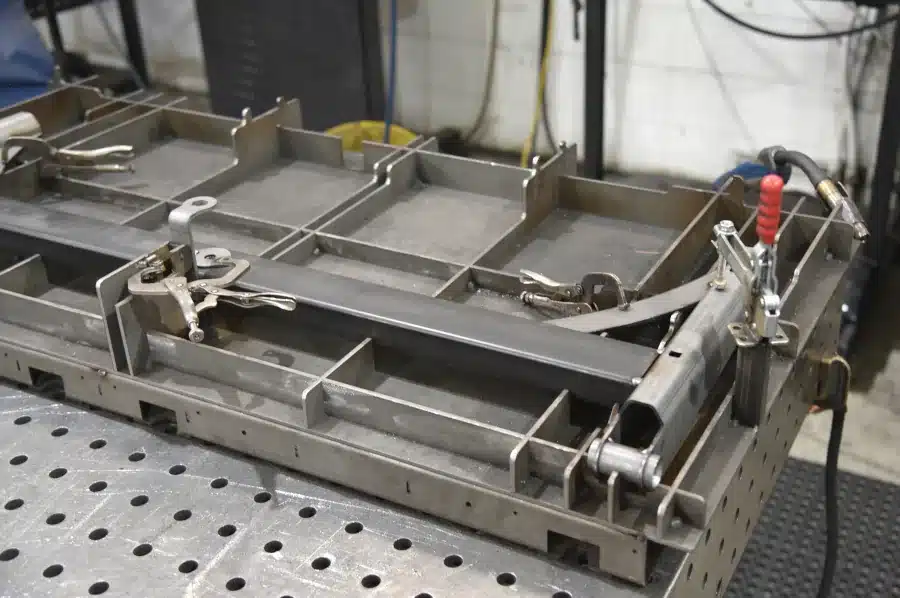

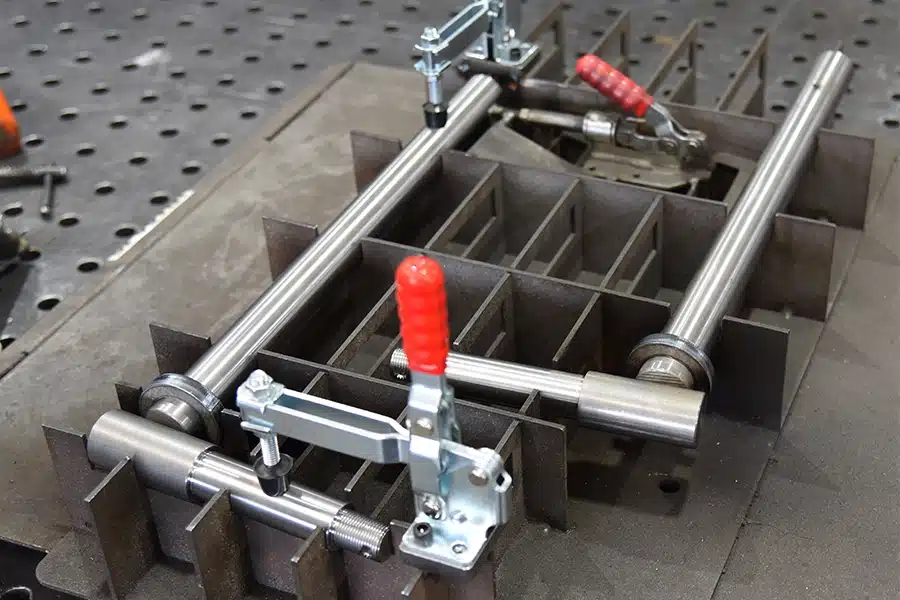

Custom Welding Fixtures Designed for Precision, Productivity, and Lean Manufacturing

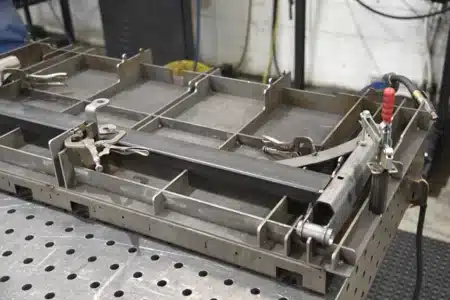

Welding fixtures are specialized tools used to hold, support, and align parts during the welding process. By ensuring accuracy and repeatability, fixtures reduce operator error, minimize rework, and improve overall weld quality. Manufacturers across industries—from automotive and aerospace to agricultural and heavy equipment rely on modular and custom fixtures to boost throughput and support lean manufacturing initiatives.

At Flextur, we design and manufacture custom welding fixtures to your exact specifications. Every fixture is engineered to solve your unique production challenges, improve workflow efficiency, and deliver long-term durability in demanding environments. Whether you need a one-off fixture or a complete system, our team partners with you from concept to completion to ensure a perfect fit for your operation.

Key Benefits of Flextur Welding Fixtures

- Custom Solutions - Tailored to multi-step assemblies or unique part geometries.

- Accuracy and Repeatability - Fixtures lock in part alignment for consistent welds, even across thousands of cycles.

- Improved Productivity - Reduce setup times, streamline training, and keep welders focused on welding—not on workarounds.

- Lean Manufacturing Support - Well-designed fixtures align with 5S and Lean principles, eliminating wasted time and movement.

- Turnkey Implementation - Fixtures arrive ready to work, fully integrated with your current tools and tables.

- Durable Construction - Made in the USA from mild steel for long-term use.

- Cost Effective - Easily adapt to minor part revisions over time without starting from scratch, or the investment of traditional fixtures.

See the Difference in Our Welding Fixtures

Every Production challenge is different and so is every Flextur fixture. Our team has designed and built solutions ranging from simple, single-part fixtures that speed up straightforward welds to complex, multi-step systems engineered for robot integration and higher throughput.

Curious how custom welding fixtures can help increase your productivity? Schedule a free consultation with our team to find out.

Why Fabricators Trust Flextur's Welding Fixtures

Reliable and Repeatable

Our Fixtures lock in part alignment to deliver precise and consistent welds across thousands of cycles. That reliability gives you confidence in every part that leaves your facility.

Increased Productivity

By reducing setup times, our fixtures let welders spend more time welding and less time on workarounds, The result is higher throughput and a smoother workflow.

Cost Effective Solutions

Flextur’s fixtures can adapt with your operation and can accommodate part revisions without the cost of starting over. You get long-term value without sacrificing quality.

Flextur’s Welding Fixture Process

Our proven 5-phase process ensures every fixture is designed, validated and shipped to meet your production needs.

“The success of any investment really comes down to how quickly it pays back against the sacrifices made to launch it. The cobots, quick change tables, and fixtures have rapidly improved our Safety, Quality and Capacity. They have been relatively easy to deploy, and we look for more opportunities to add more throughout our transformation. These projects have been a win all around.”

- Glenn Zimmerman, Manufacturing Engineering Manager, Modine, Jefferson City, MO

Weld Fixturing Q&A

Flextur: Smarter Welding Fixtures for Modern Manufacturing

Better fixturing means better throughput. With Flextur, you gain more than fixtures. You gain a partner committed to helping you achieve precision and efficiency in every weld. From prototypes to full-scale production, we’re here to help.