5 Key Features of a 5S Workstation & How to Build One

In manufacturing, welding, assembly, or maintenance environments, efficiency, safety, and organization aren’t optional, they’re essential. That’s where a 5S workstation comes in. Built around the Lean manufacturing principles of Sort, Set in Order, Shine, Standardize, and Sustain, a 5S workstation isn’t just tidy, it actively improves workflow, reduces downtime, and keeps operators safe.

What Makes a 5S Workstation Different?

Unlike a standard workstation, which might simply have tools nearby and surfaces to work on, a 5S workstation is intentionally designed around both workflow and operator use. Every element is organized to improve efficiency, safety, and consistency. Key benefits include:

- Tools are always easy to find, reducing wasted time

- Workflows are predictable and repeatable, streamlining operations

- Safety hazards are minimized, keeping operators protected

- The station actively supports Lean goals, from quality to throughput

The 5 Key Features of an Effective 5S Workstation

1.

Clearly Labeled, Designated Tool Locations

Every tool, part, or accessory has a specific, visible “home.” This eliminates wasted time searching and ensures consistency.

How to implement:

- Use shadow boards or tool outlines

- Label hooks, bins, and drawers

- Group items logically by function or frequency of use

- Place heavy-use tools close to the work zone

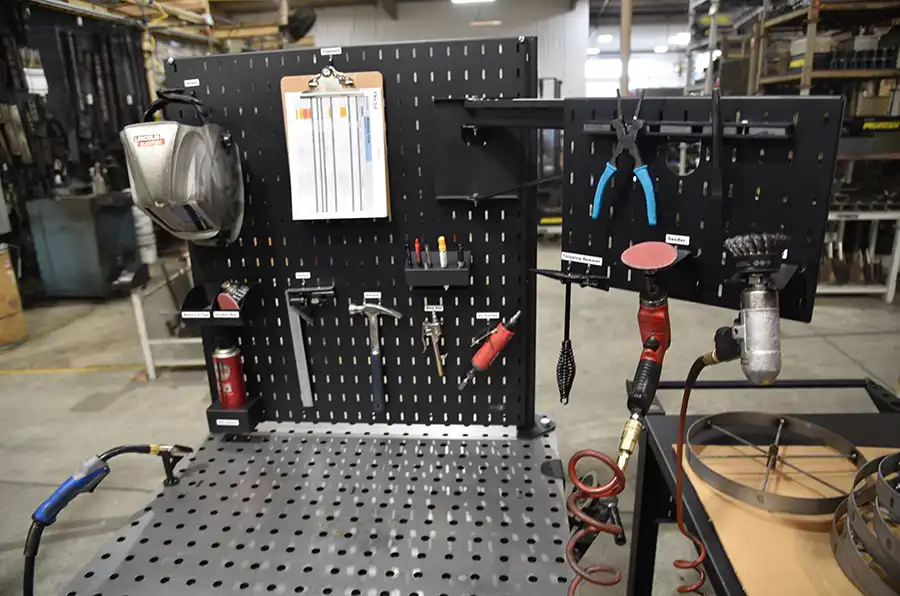

Example: A station with a pegboard where every part has a clearly labeled, dedicated spot so anyone can see exactly where everything belongs, no guessing, no searching.

2.

Workflow-Driven Layout

The station is designed around how the work actually happens, not how it looks.

How to implement:

- Keep high-use tools within arm’s reach

- Store rarely used tools off to the side

- Arrange the station to minimize unnecessary motion

- Define zones for prep, work, and finished parts

Example: In a packaging or shipping workstation, materials should be organized so the operator can move from packing to sealing to labeling without backtracking or searching creating a smooth, repeatable flow.

3.

Clean, Clutter-Free Surfaces

Cleaning shouldn’t be a chore, it should be simple. A 5S workstation is easy to maintain, which helps keep it safe and efficient.

How to implement:

- Wipeable surfaces for quick cleaning

- Minimal “parking spots” for unused items

- Proper cable and hose management

- Accessible trash and scrap bins

Example: A workbench with integrated hooks, bins, trays for tools and organized hardware, so the operator not only has and clean surface to work on with all tools in reach but can clean up in under two minutes.

4.

Visual Standards and Controls

Operators need to know exactly what “organized” looks like. Visual standards make it easy to maintain the system and train new team members.

How to implement:

- Color-coded tools or zones

- Posted checklists or procedures

- Photos of the ideal workstation layout

- Red tag areas for items that don’t belong

Example: A maintenance station with all tools in place, plus labels on bins and drawers to reinforce organization.

5.

Durable, Purpose-Built Components

The best workstations are built to last. Cheap or flimsy components will fail, and the system collapses.

How to implement:

- Steel pegboard panels

- Heavy-duty benches and carts

- Sturdy shelves and bins

- Quality hardware for mounting

Example: A welding workstation that can withstand heat, slag, and heavy-duty use without bending, sagging, or breaking.

Operator Ownership & Ongoing Maintenance: The Real Key to 5S Success

The most successful 5S workstations are those where operators take ownership and help shape the station’s design. When they have a say in how the workspace is organized, they’re naturally invested in maintaining the 5S standards.

And, like any effective system, 5S isn’t a “set it and forget it” project. Ongoing maintenance, including daily wipe-downs, weekly audits, and monthly layout reviews, are essential to sustain efficiency, safety, and workflow improvements over time.

If you’re looking to build or improve a 5S workstation, our team can help you design a setup that fits your workflow and supports your Lean goals. Connect with our team for a quick conversation about the project you’re working on.