Avoid These 5 Costly Mistakes When Buying a Welding Table

A welding table isn’t just a work surface; it’s the foundation of your entire fabrication process. When investing in welding tables, the right choice improves setup efficiency, accuracy and overall workflow. Here are five common mistakes to avoid when buying a welding table, and what to look for instead.

Reinforced struts prevent warping and ensure consistent accuracy

1.

Ignoring Flatness and Structural Integrity

Table flatness directly affects weld accuracy. Even slight warping or uneven surfaces can throw off alignment, causing inconsistent results and costly rework. Choose tables that are engineered for surface accuracy and reinforced with structural bracing to maintain flatness under load. Flextur weld tables are supported by 3/8” x 5” struts every 16” which provide surface flatness of +/-.015 over 4 square feet ensuring precision, repeatability, and quality control in every weld.

Flextur’s ½″ steel tabletop maintains strength and flatness for precision welding

2.

Choosing a Thin or Low-Grade Tabletop

The material your table is made from determines its strength, durability and ability to withstand high heat. Look for welding tables built from high-gauge steel tops for lasting flatness and load capacity. Flextur weld tables use a ½” steel top, delivering the durability needed for high-frequency welding, heavy components and demanding production environments.

Modular designs adapt quickly to different projects and part sizes

3.

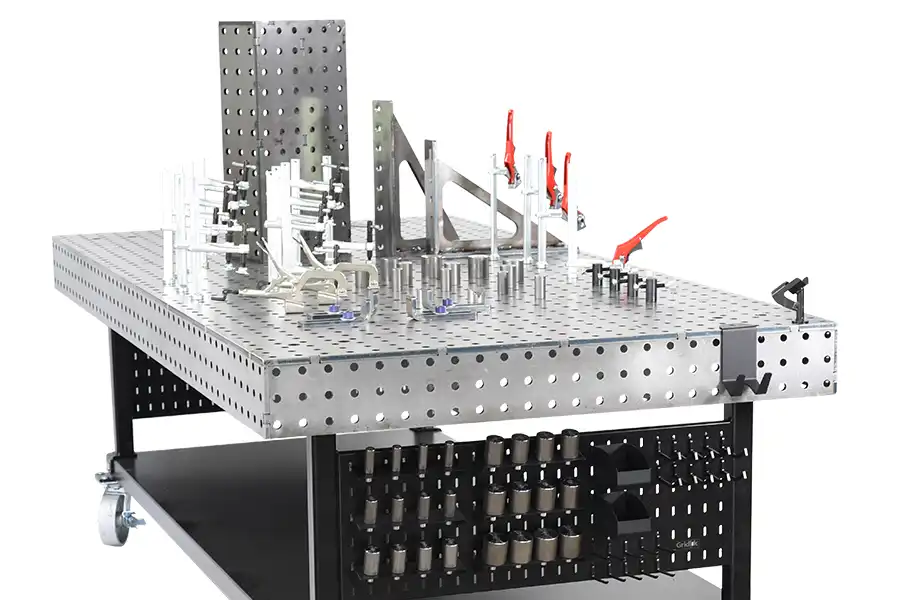

Overlooking Modular and Configurable Options

Static tables limit flexibility, and your welding needs will evolve. New projects, larger parts or cobot integration often require different setups. Invest in modular welding tables with adjustable fixtures, they save setup time and adapt easily as your production changes. Flextur offers a variety of modular tables and fixture kits that grow with your production needs. The Flextur Fixture Block also allows you to extend tables with skirts horizontally to create the size you need, and it also allows you to tie two tables together if needed for larger parts. This versatility helps optimize workflow, scale complexity and increase throughput with each table investment.

Flextur’s Nitride+ finish resists corrosion and extends table life

4.

Disregarding Corrosion-Resistant Surfaces

Unprotected tables rust quickly, increasing downtime and maintenance costs. A corroded surface also interferes with grounding and part contact. Look for surface treatments such as nitriding. Flextur’s Nitride+ tables offer a powerful combination of nitriding and black oxide treatment. Together they harden and prevent corrosion, extend the life of the table and reduce total cost of ownership. A properly finished surface minimizes fabrication delays and keeps your team focused on production, not upkeep.

Proper table height supports comfort and long-term productivity

5.

Underestimating Ergonomic Design

A well-designed table does more than just hold parts. It supports your team’s comfort and efficiency. Tables with adjustable heights, and clear access for fixtures and parts help welders work more comfortably and stay productive longer. All Flextur stationary 4x4 and 4x8 tables include adjustable legs from 35” to 41” high.

Build Your Foundation Right

Avoiding these five mistakes ensures your welding table investment pays off in productivity, accuracy and long-term reliability. A well-engineered table not only improves your workflow, but it also transforms how you approach every weld.

Explore Flextur Welding Tables engineered for real-world performance, built by welder who know what it takes to get the job done right.