Engineering Considerations When Selecting a Welding Table for Automation and Precision Work

In many fabrication and manufacturing environments, the welding table plays a larger role in process quality than it’s often given credit for. Whether a team is implementing robotic welding, working with cobots, or simply aiming to reduce variation in manual welding, the table becomes an important foundation for consistent results.

Why Welding Table Selection Matters

A welding table directly affects alignment, fixture accuracy, and the repeatability of welded assemblies. Even minor variations in flatness can influence weld quality, slow down setup time, or contribute to rework, especially when robotics or precision fixturing are involved.

The right table often helps teams improve in areas like these:

- Dimensional accuracy when a stable, flat surface supports precise fixturing

- Repeatability across batches and shifts

- Setup efficiency, particularly in high‑mix environments

- Robotic performance, where consistent surfaces support accurate path execution

Key Engineering Factors When Choosing a Welding Table

Selecting the right Welding Tables is ultimately about building a platform that supports accuracy, repeatability, and ease of use. The following factors typically shape long-term quality and productivity.

Understanding Flatness and Structural Rigidity

A stable, uniformly flat surface ensures fixtures sit correctly and minimizes errors. Structural rigidity plays a major role; a table that flexes or deflects under load makes consistency harder to achieve.

Flatness Tolerances and Their Impact on Weld Quality

Even small deviations can shift fixture locations and accumulate as dimensional errors, affecting part fit‑up and robotic path repeatability. For precision workflows, tighter flatness across the active work area helps maintain CAD‑to‑physical alignment.

How Structural Bracing Supports Long-Term Accuracy

Thicker tabletops, reinforced internal supports, and well‑designed bracing help maintain flatness both during daily use and over the long term, minimizing deflection under static and dynamic loads.

Material Options and Surface Treatments for Welding Tables

Different materials offer distinct characteristics that can benefit specific applications.

Steel vs. Cast Iron Welding Tables

Steel tables are preferred for their high strength-to-weight performance and cost efficiency, making them ideal for most industrial environments. Cast iron tables, while heavier and more expensive, offer superior vibration damping, which is beneficial in high-precision or micro-welding applications where even small vibrations can affect weld quality.

Benefits of Nitride and Hardened Surfaces

Surface treatments such as nitriding or dual-layer coatings improve resistance to weld spatter, abrasion, and corrosion. Hardened surfaces minimize cleanup time, reduce wear on fixturing components, and extend table service life while maintaining a consistent plane.

Modular Fixturing and Hole Grid Systems

A consistent hole grid allows operators to build accurate fixtures quickly and repeatably. Standardized hole spacing enables rapid fixturing and repeatable setups, which is especially valuable in high‑mix, robotic, prototyping, and batch production environments.

Evaluating Load Capacity and Long‑Term Stability

A welding table should support not only the weight of the workpieces but also fixturing hardware, positioners, and collaborative robot mounts when applicable. Selecting a table with generous load overhead improves long term stability and reduces risk of permanent deformation.

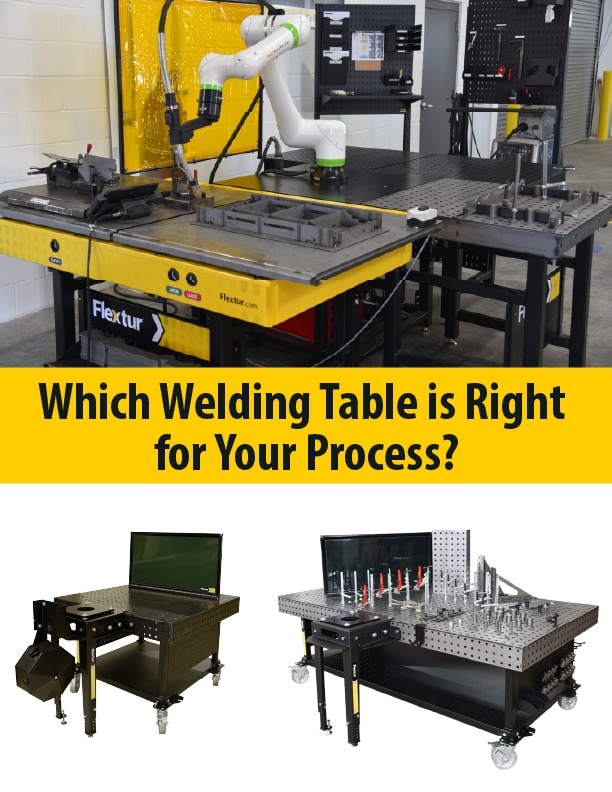

How Flextur Welding Tables Support Precision and Repeatability

Flextur welding tables are designed with many of the performance requirements, making them well-suited for both robotic welding and collaborative robot (cobot) integration.

Structural Design

Built with a ½ inch steel tabletop supported by 3/8 inch x 5 inch structural struts spaced every 16 inches; these tables deliver exceptional torsional rigidity and maintain flatness under demanding loads. Load capacity commonly exceeds 1,000 pounds, supporting both manual and automated applications.

Precision Flatness

Flextur tables maintain ±0.015 inches of flatness across a 4 square foot area. This level of precision is well suited for robotic welding, repeatable fixtures, and high-tolerance assemblies.

Modular Fixturing

A 2 inch grid pattern with 16 mm locator holes enables rapid fixture rearrangement and high repeatability. This system supports CAD aligned workflows and drastically reduces setup time.

Quick‑Change System

Flextur’s pneumatic Quick Change system allows fixture plates to be swapped quickly while maintaining precise alignment. This is particularly advantageous in automated production where downtime is costly and repeatability is essential.

Surface Options

- Plain Steel for standard applications

- Nitride+ hardened finish for spatter resistance, corrosion protection, and long-term surface integrity

The Nitride+ option provides significant hardness and wear resistance, ideal for high volume or robotic welding environments.

Selecting a welding table is ultimately about choosing a platform that supports accuracy, repeatability, and ease of use. While many factors influence weld quality, the table is one of the most controllable variables in the process.

A thoughtful selection can help teams improve workflow efficiency, support automation initiatives, and maintain more consistent results across the board. If you’re evaluating options or planning future upgrades, we’re always available to help you compare configurations and choose the best fit for your applications.

Need Help?

Download a comparison chart to help you find the table that fits your needs.