When is the right time to build a welding fixture?

Welding fixtures ensure consistent quality, optimize the welding process, and reduce defects. With the welding industry facing a skills gap, these fixtures become increasingly important as they lessen the dependency on welder skills, aiding in training novices and maintaining quality across varying expertise levels.

Incorporating welding fixtures during product design or prototyping is ideal for correct component positioning. Deciding when to use a welding fixture involves considering project complexity, production volume, financial implications, and the team's skill level.

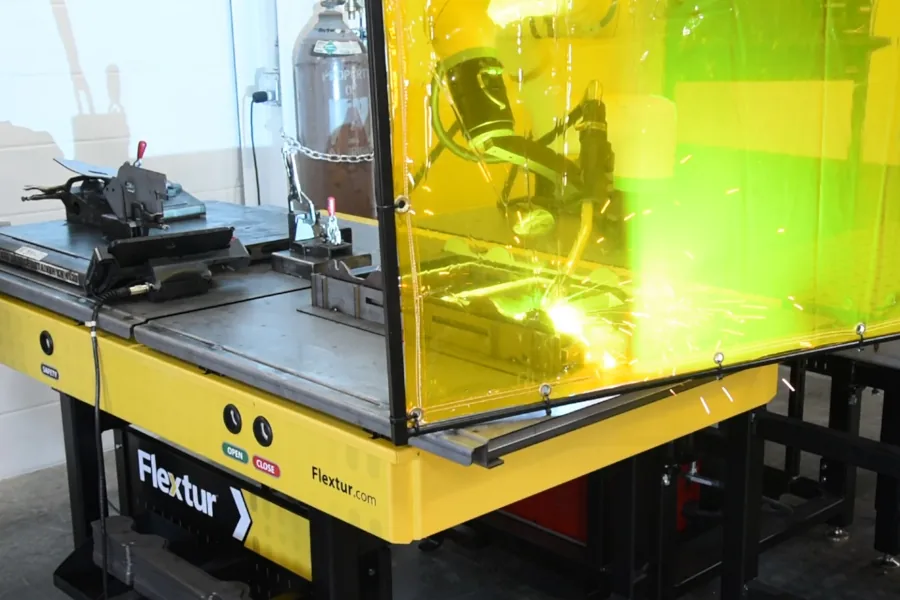

A good fixture offers precision, durability, and ease of setup, supporting parts securely while allowing for efficient welding. Understanding the best type of fixture for a task is also pivotal, ranging from basic configurations to more advanced and automated systems. Ultimately, using welding fixtures enhances precision, efficiency, and overall weld quality while reducing dependency on operator skill.