Join Us At:  Chicago, September 11-14 • Booth #B11054

Chicago, September 11-14 • Booth #B11054

Have a Cobot that is Under Utilized?

Integrate existing welding Cobots or new Cobots into Flextur’s Cobot Welding System to create an extremely accurate, efficient, safe, repeatable and highly productive welding cell.

Using our patent pending Quick-Change Fixture Table and Quick-Change Fixture Plates to ensure that your parts are positioned and clamped in the exact spot every time (+/- 0.015"), allowing you to create highly accurate, repeatable, automated workflows.

Switch to a different part in minutes.

Release the pneumatic quick-detach welding Fixture Plate and return it to the Quick-Change Fixture Plate storage solution that fits your needs. Choose the next Quick-Change Fixture Plate and safely clamp it into position with the touch of a button. Select your new program and keep your workflow humming.

Have Questions? Contact Us.

The Time to Take Action is Now!

Forecast: 400,000 less welders will be in the workforce by end of 2026.

The Flextur Cobot Welding System solves these three major issues:

Faster Change Overs Increase Arc On Time.

The ideal solution for high mix low volume parts, with less downtime and the ability to do offline part setup. A Flextur customer using the Flextur Cobot Welding System increased productivity from 20 manually welded parts per day to 80 parts per day. A 300% Increase in productivity. In another example, set up time was reduced from over 45 minutes to under 5. A 900% increase in efficiency, creating more Arc On Time.

Ease of Use – Simplicity & Repeatability

This benefit of a Cobot is often lost when it comes to holding parts or fixturing. There are always complexities setting up a part or changing to a new part. Additional challenges occur designing a productive work flow or maintaining operations after the first shift automation engineer or tech leave for the day. These challenges are often why Cobots become under-utilized, or even worse… pushed into a corner. The Flextur Cobot Welding System featuring Quick-Change Fixture Tables solves these complex issues in a simple way that works.

Transitioning Your Team From Hand Welding to Automation.

This is especially important in times of skilled labor shortages in the welding sector. The Flextur Cobot Welding System makes difficult welding applications accessible to AWS Certified Welders with the tools they need to be more productive. Allowing manual welders to transfer knowledge to automation without the hurdle of more advanced programming necessary when trying to complete similar tasks with a traditional robot.

In summary, Flextur’s Cobot Welding System creates an extremely accurate, efficient, safe, and highly productive welding cell. A modular system that greatly simplifies fixturing and repeatability within the welding process. We reduce complexity by creating a system that anyone can walk up to and change over in minutes. A turnkey solution for the Cobot environment to reduce the time from last good part (Part “A”) out - to first good part (Part “B”) out.

Interested In Having Flextur Create Fixtures For You?

Flextur can assist anyone using a Flextur Cobot Welding System by designing and/or building fixtures for their specific application. We have decades of experience in Contract Manufacturing, utilizing automation and fixtures. Today, with our investment in software like Cenit for offline programming, SolidWorks and Camtek we are able to affordably and efficiently create work cells and fixtures remotely, as well as on location. Stop by the Flextur booth #B11054 at Fabtech for more details on how Flextur can solve complex fixturing issues with simple solutions that work.

The Modular Design of the Flextur Cobot Welding System adapts with you.

Whether you are getting your first cobot, or your 21st cobot. Or, if you’ve been using fixtures or you just got your first welding table, Flextur’s Cobot Welding System can meet you where you are. And it will easily adapt and grow with you, as you become more advanced in your cobot usage.

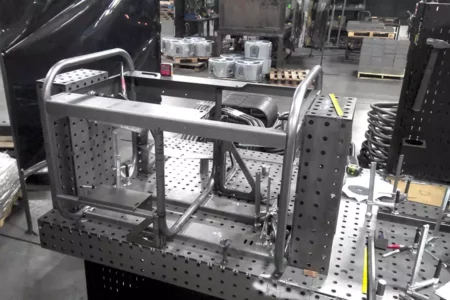

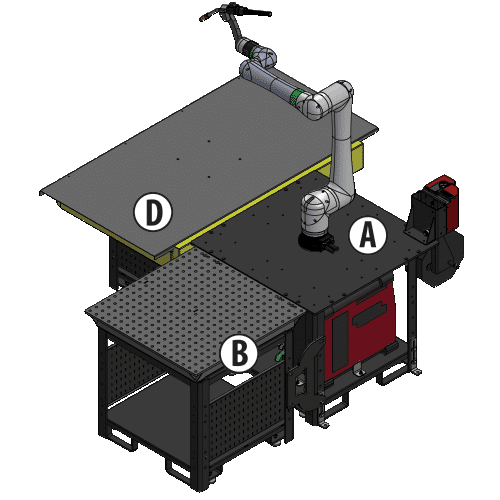

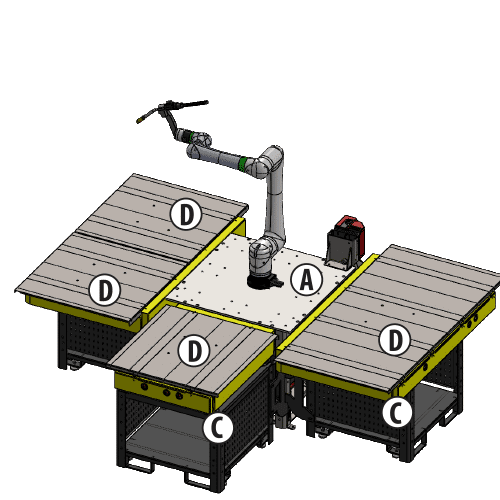

Flextur Cobot Docking Station

The Flextur Cobot Docking Station is the heart of the Flextur Cobot Welding System. Your cobot, cobot controller, power supply and wire feeder will be mounted to this rugged, fork-able base. Because all of the other table options mount to and work with the Docking Station it is recommended that it be securely bolted to the floor.

Flextur Cobot Tables

Flextur Cobot Tables are available in 36”x36” and 72”x36”. These nitrated tables easily bolt up and accurately align and level to the Flextur Cobot Docking Station. These are great tables for prototyping, or scenarios where the pricing, volume or job do not merit a fixture. Tables also utilize Gridlok Technology, allowing you to keep the tools or parts you use most close at hand.

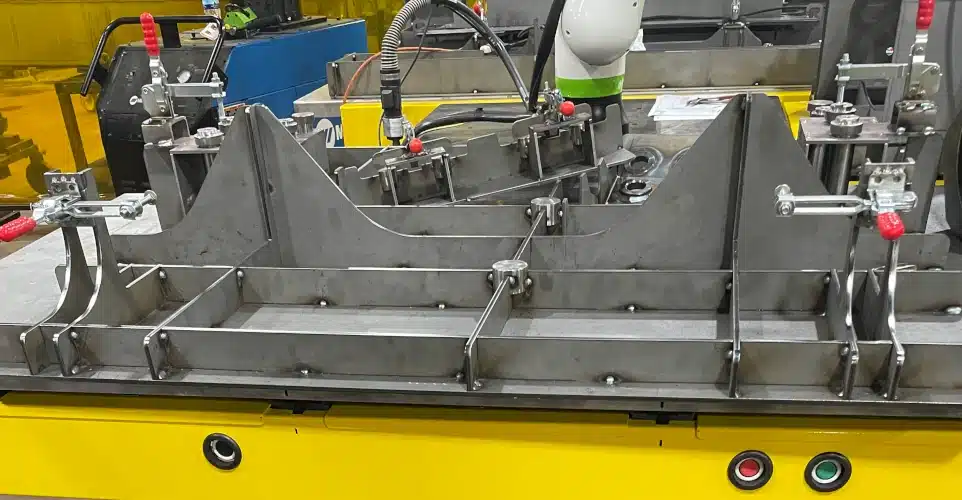

Flextur Quick-Change Fixture Tables

If you are like the majority of Cobot owners we’ve spoken to, you are doing a high mix of low to mid volume parts. You feel your Cobot is under utilized and you’re struggling with how to maximize your Cobot investment? The patent pending Flextur Quick-Change Fixture Table is the only one of its kind. It allows you to create highly accurate, repeatable, automated workflows that increase productivity in a big way. This frees up your Automation Engineer, Cobot Technician and Experienced Welder for other things, while the Cobot Operator simply burns wire and makes parts. Changing parts is as simple as releasing the pneumatic quick-detach Quick-Change Fixture Plate and returning it to the Quick-Change Fixture Plate storage rack. Choose the next Quick-Change Fixture Plate and safely clamp it into position with the touch of a button. Select the new program and keep your workflow humming.

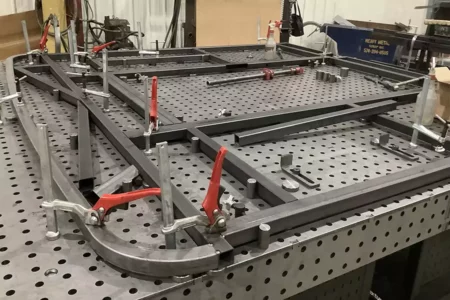

Quick-Change Fixture Plate

These durable plates are engineered to be positioned and clamped in the exact spot every time on the Flextur Quick-Change Fixture Table. How accurate you ask? Plates are within +/- 0.015" every time. These serve as a consistent base for any fixtures. Our Quick-Change Fixture Plates work with all types of fixtures, from basic welded stops and clamps to the latest full 3D designed tab and slot fixtures. Flextur can assist anyone using a Flextur Cobot Welding System by designing and/or building fixtures for their specific application.

Flextur Products Featuring

To further support your Flextur Cobot Welding System, Flextur has offload tables, grinding stations, traditional welding tables, and mobile tool board solutions perfect for 2 bin systems suppling materials to your Cobot or Robotic Welding System. Keeping the materials and finished products flowing to and from your Flextur Cobot Welding System is critical when trying to reach greater operational efficiency. All Flextur products feature Gridlok Innovation. This patented Innovation is most evident on our Tool Board System that holds 50lbs on a single industrial hook, and with some accessories capable of even more. This robust system allows you to keep all the tools and parts you need within easy reach.

Is CapX Holding You Back?

Rent a Flextur Cobot Welding System Today.

You can’t afford to waste another unproductive day. Getting started is simple, especially if you already have an under-utilized Cobot to integrate. Flextur’s Automation Team will work with you to assemble the right Cobot Welding System and Support Products to create an extremely accurate, efficient, safe, and highly productive welding cell that you can rent, rent to own, or of course purchase. In addition, Flextur can assist anyone using a Flextur Cobot Welding System by designing and/or building fixtures for their specific application. What’s holding you back? Stop by the Flextur booth #B11054 at Fabtech for more details.

Not Getting the Training and Support You Need?

Rent a Flextur Cobot Welding System Today.

With this training your team will not only learn about the Flextur Cobot Welding System and the Quick-Change Fixture Table, but the differences between Cobots and Robots. basic operation, trouble shooting, program touch ups, how to deal with crashes, fixturing does and don’ts and more. Let your team tap into our decades of experience in Contract Manufacturing, utilizing automation and fixturing. Automation Teams can also see the power of our investment in software like Cenit for offline programming, Solidworks and Camtek for part and fixture design. Stop by the Flextur booth #B11054 at Fabtech for more details.

Flextur Contract Metal Manufacturing & Solution Providers.

We provide the best contract manufacturing solutions for high quality, mid volume steel products delivered on time. Do you struggle to hit production goals, or QC requirements? Are you seeking ways to increase throughput while decreasing overall cost through labor, materials, or process & product improvements? Flextur Contract Manufacturing can help you meet these challenges. A Strategic Partner providing Cut, Form, Machine, Weld, and Coat Services on a single PO.